Along with being assigned the role of Lead Programmer I was asked by the Project Manager to create an initial program design in order to begin testing as soon as the circuit board had been built.

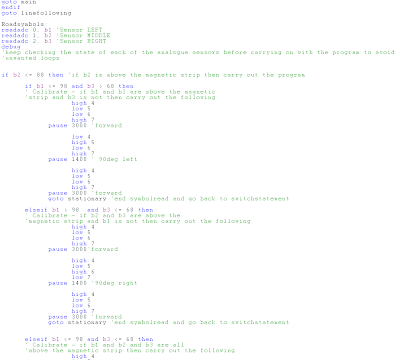

The following is the experimental program which will be tested for the buggy project

_____________________________________________________________

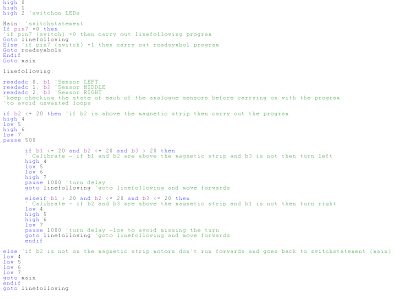

Main: 'switchstatement

If pin7 =0 then 'if pin7 (switch) =0 then carry out linefollowing program

Goto linefollowing

Else 'if pin7 (switch) =1 then carry out roadsymbol program

Goto roadsymbols

Endif

Goto main

linefollowing:

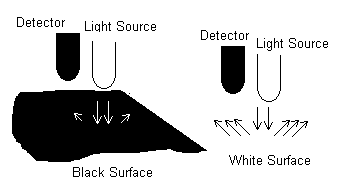

readadc 0, b1 'Sensor LEFT

readadc 1, b2 'Sensor MIDDLE

readadc 2, b3 'Sensor RIGHT

'keep checking the state of each of the analogue sensors before carrying on with the program to avoid unwanted loops

if b2 > 50 then 'if b2 is above the magnetic strip then carry out the program

high 1

low 2

high 3

low 4

'time delay?

goto sideresleft 'first check to see if left sesor has become activated

else

low 1

low 2

low 3

low 4

goto main

'if b2 is not on the magnetic strip motors don't run forwards and goes back to switchstatement (main)

endif

goto linefollowing 'repeat

sideresleft:

if b1 > 50 and b2 > 50 and b3 < 50 then

' Calibrate - if b1 and b2 are above the magnetic strip and b3 is not then turn left

high 1

low 2

low 3

high 4

pause 1000 'turn delay

goto linefollowing 'goto linefollowing and move forwards

else

goto sideresright

' if conditions are not met left sensor is not above the magnetic strip therefore move to check if the right sensor has moved above the magnetic strip before returning to the linefollowing program

endif

sideresright:

if b1 < 50 and b2 > 50 and b3 > 50 then

' Calibrate - if b2 and b3 are above the magnetic strip and b1 is not then turn right

low 1

high 2

high 3

low 4

pause 1000 'turn delay -low to avoid missing the turn

goto linefollowing 'goto linefollowing and move forwards

else

goto linefollowing

'if conditions are not met return to linefollowing program and carry on forwards

endif

roadsymbols:

readadc 0, b1 'Sensor LEFT

readadc 1, b2 'Sensor MIDDLE

readadc 2, b3 'Sensor RIGHT

'keep checking the state of each of the analogue sensors before carrying on with the program to avoid unwanted loops

if b2 >= 50 then

' middle sensor must be placed over magnetic strip line for the program to be executed or it returns to switchstatement

high 1

low 2

high 3

low 4

pause 500 'moves forward to read symbol

if b1 >= 50 and b2 >= 50 and b3 < 50 then

' Calibrate - if b1 and b2 are above the magnetic strip and b3 is not then carry out the following

high 1

low 2

high 3

low 4

pause 1000 'forward

low 1

high 2

high 3

low 4

pause 300 ' 90deg left

high 1

low 2

high 3

low 4

pause 1000 'forward

goto stationary 'end symbolread and go back to switchstatement

elseif b1 >= 50 and b2 >= 50 and b3 >= 50 then

' Calibrate - if b1 and b2 and b3 are all above the magnetic strip then carry out the following

high 1

low 2

high 3

low 4

pause 1000 'forward

low 1

low 2

low 3

low 4

pause 1000 'stop

low 1

high 2

low 3

high 4

pause 1000 'reverse back to start

goto stationary 'end symbolread and go back to switchstatement

elseif b1 < 50 and b2 >= 50 and b3 >= 50 then

' Calibrate - if b2 and b3 are above the magnetic strip and b1 is not then carry out the following

high 1

low 2

high 3

low 4

pause 1000'forward

high 1

low 2

low 3

high 4

pause 300 '90deg right

high 1

low 2

high 3

low 4

pause 1000 'forward

goto stationary 'end symbolread and go back to switchstatement

endif

else

goto stationary

endif

goto roadsymbols

stationary:

low 1

low 2

low 3

low 4

goto main

___________________________________________________________

Posted by Sandra Donohoe