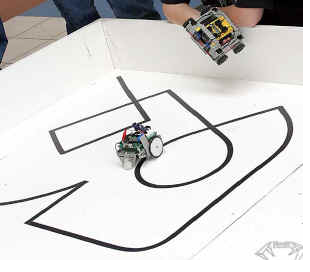

Line follower concept

Design “shell” ideas:

Layers

Putting several sheets of e.g. acrylic stacked on top of each other provides the opportunity to have a smaller buggy, to hopefully reduce weight and not allow the machine to be large enough to lose course once approaching a sharp bend on the path.

Wheels

A three wheeled system allows for better control of the buggy, where two (positioned either at the front or the rear) are each connected to a motor and the final smaller wheel is allowed to pivot based on the behaviour of the larger steering wheels.

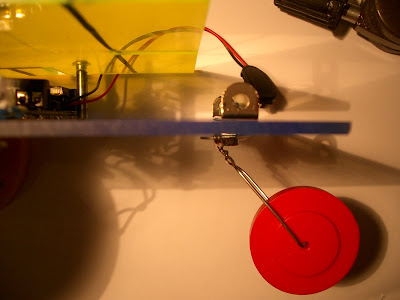

Sensor Board locationThe sensor board will be located close proximity to the ground and covered. This is required to avoid analogue readings (from the LDR) being influenced by a combination of LED and unwanted ambient light input.

Note: the sensor should be positioned between 1/16" to 1/8" above the ground

LED light housing

• Tubular to cover each sensor and LED (plastic)

• Block (e.g. Lego) to cover the LDR and its paired LED

Sensor LDR sensor has been selected as the most appropriate sensor; alternatives included photo transistors, magnetic sensors...

However when tested the strip was found not to have produced a high enough field intensity to obtain the required analogue readings that would be used to control motor behaviour, therefore magnetic sensors were not used.

http://www.fastcharged.org/robotics/firstrobot

http://www.micahcarrick.com/files/failurebot5/complete.jpg

http://www.robotgames.net/robotgames/Event_Rules/2002_line_follower.htm

http://www.ermicro.com/blog

http://www.esskayinstitute.com/LFROBOBLK.jpg

http://www.robotroom.com/NumberTwo9.html

http://www.leang.com/robotics/info/articles/linesen/pcb1.jpg

The group decided that it was best for the design to be layered and to have the LEDs and sensor on the front at the bottom.

The group decided that it was best for the design to be layered and to have the LEDs and sensor on the front at the bottom.